CNC Manufacturing

At BOMAFA we understand the criticality of the components that are manufactured to produce our Valves. As a continuous improvement process we have CNC machines that work on producing the components with highest accuracy and close tolerances. Our installed battery of CNC machines ensures 100% quality check in-house.

Welding

Complete welding for all the valves are 100% done in-house with our welding team. We have welders that are qualified to carry out welding as per IBR, and ASME SEC-IX requirements. Welders are qualified for dissimilar material right from SA 105 to F 92 by third party agencies like Lloyds, TUV.

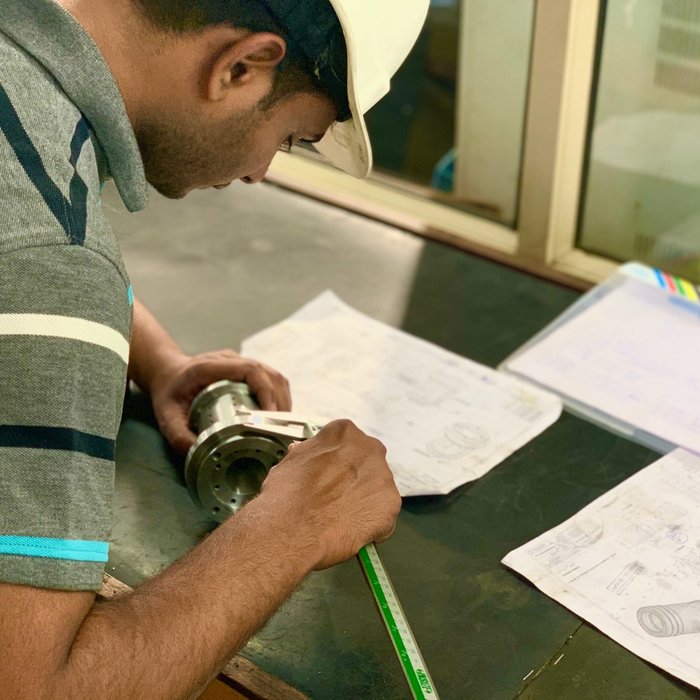

Mounting

We have full-fledged test facility to check and inspect all the mountings and assembly of the valves in-house. This would include hydro testing, seat leakage, calibration, dimensional check for the valves to ensure they are defect free and perform for years at site.

Quality Assurance

Our valves pass through most vigorous and stringent tests during manufacturing, assembly and testing stages. All the valves are given an individual serial number that will remain with BOMAFA for eternity. This would enable customer to approach us with relative ease after years for any requirement of spares by just referring that number. All the products are supplied with complete internal test reports.